Reverse engineering is a powerful process that allows industries to deconstruct and analyze existing products, components, or systems to understand their design, functionality, and structure. This technique is widely used across various industries, including automotive, aerospace, healthcare, and manufacturing, to enhance product development, optimize designs, and improve efficiency.

Reverse engineering involves dismantling and analyzing a product to extract knowledge about its design and function. This process enables manufacturers to recreate or enhance products without needing original blueprints or documentation. It is often used to replicate discontinued parts, improve existing products, and develop innovative solutions based on competitor analysis.

Automotive Industry – Reverse engineering helps in redesigning vehicle components, enhancing performance, and developing replacement parts for legacy models.

Aerospace Sector – The technology assists in maintaining and upgrading aircraft components by recreating obsolete parts and improving aerodynamics.

Healthcare & Medical Devices – Engineers use reverse engineering to develop prosthetics, medical implants, and surgical instruments tailored to patient needs.

Manufacturing & Tooling – It aids in optimizing production processes, improving machinery design, and ensuring compatibility with new technologies.

Electronics & Consumer Goods – The process enables companies to analyze competitors’ products, improve existing designs, and develop cost-effective alternatives.

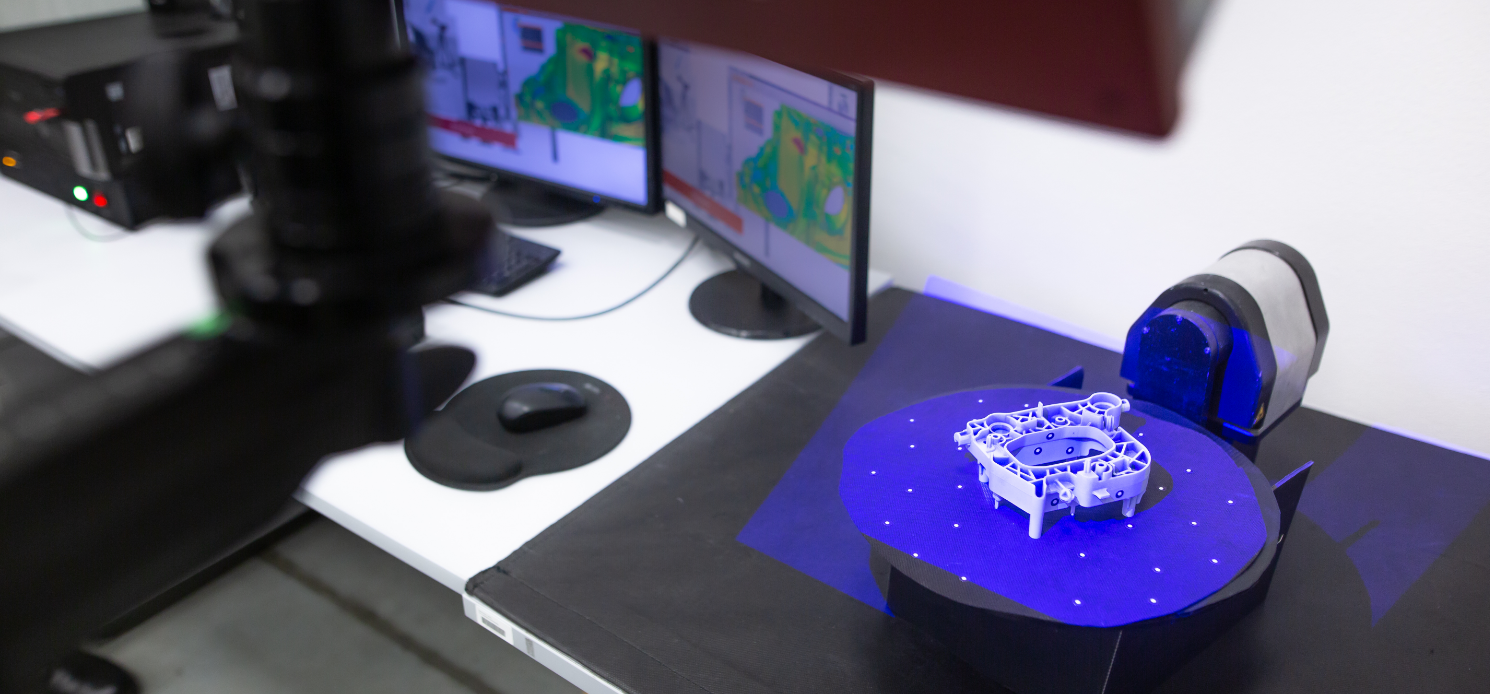

3D Scanning & Imaging – Capturing precise digital representations of physical objects.

CAD Modeling – Creating detailed computer-aided design (CAD) models for manufacturing.

Additive Manufacturing & 3D Printing – Prototyping new or improved components.

Material Analysis – Determining the composition and properties of materials used in manufacturing.

Reverse engineering allows for refining and improving existing designs to enhance performance.

Enables reproduction of obsolete or unavailable components without original design data.

Reduces development time and expense by replicating or modifying existing products.

Fosters innovation by analyzing competitor products or integrating new features into existing designs.

Reverse engineering has become an essential tool for modern industries, allowing companies to stay competitive by improving designs, reducing production costs, and extending the usability of existing components. With advancements in digital scanning and 3D modeling, the process is now more efficient and accurate, making it a crucial aspect of industrial innovation.

For any product development

inquiries contact us

How can we help you? Feel free to get in touch!