Perfect for strong, precise parts for any machine or product

Protosys Technologies specializes in Additive Manufacturing (3D Printing), a process that transforms a 3D CAD design into a physical part by building it layer by layer. Unlike traditional manufacturing, it requires no molds, tooling, or machining setups, allowing parts to be produced directly on the print bed with speed and flexibility. This technology is ideal for rapid prototyping, low-volume

Additive manufacturing builds parts layer by layer using materials like filaments, powders, liquids, or sheets, through jetting, extrusion, photo-curing, laminating, or fusing.

Product development is much faster compared to traditional manufacturing.

Each and every part can be customised according to every need.

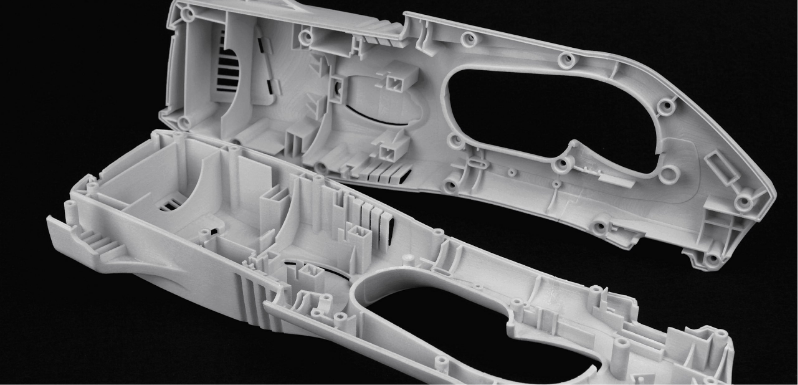

Parts with complex geometry are easily printed and as simple parts.

Additive Manufacturing allows production of 1 part or 100 parts.

Additive manufacturing involves various processes where parts are built layer by layer using materials like filaments, powders, liquids, pastes, or sheets. These materials are shaped through jetting, extrusion, photo-curing, lamination, or fusion techniques.

SLA is an additive manufacturing process where a UV laser cures liquid resin layer by layer to build a 3D object. The design is traced onto the resin surface, and the build platform lowers incrementally after each layer. Once complete, the part is post-cured under UV light for enhanced durability.

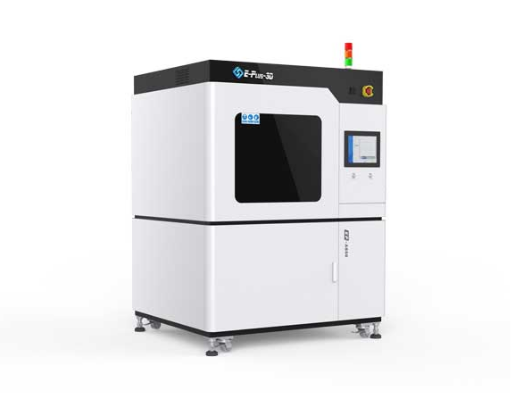

SLS is an additive manufacturing technique where a CO2 laser fuses powdered material layer by layer based on 3D CAD data. The laser selectively sinters the powder, creating solid structures. After each layer is sintered, the platform lowers, and fresh powder is spread over the part until the object is fully built, then excess powder is removed.

MJF is an advanced additive manufacturing process using HP Thermal Inkjet technology to rapidly and precisely produce parts. Fusing, detailing, and colouring agents are applied layer by layer, bound by energy, with air cooling completing the ready-to-use parts.

DMLS is a metal 3D printing process where a laser fuses metal powder layer by layer. The build platform lowers with each layer, and the part undergoes post-processing for strength and finish.

FDM is a widely-used additive manufacturing process where thermoplastic material is heated and extruded through a nozzle to build parts layer by layer. The material solidifies as it cools, and the build platform lowers incrementally to form the final part. It’s ideal for rapid prototyping and functional parts.

Resins are ideal for parts that require high finesse and detail. The resin is a photopolymer in the form of a viscous liquid that requires a light source to produce and cure a desired part. Protosys Technologies offers Accura 25, Accura 60, and ABS.

Nylon powder is used extensively in SLS as it is very flexible, offers good heat and chemical resistance, and the unsintered powder acts as a support to the part that is manufactured. Protosys Technologies offers PA6, PA12 glass-filled.

Metal powders are used mainly in DMLS and produce parts for high-end engineering applications. The metal parts produced have high strength, high hardness, and high thermal capacity. Protosys Technologies offers Stainless Steel, Aluminium, and Titanium.