Perfect for high volume plastic parts at consistent quality

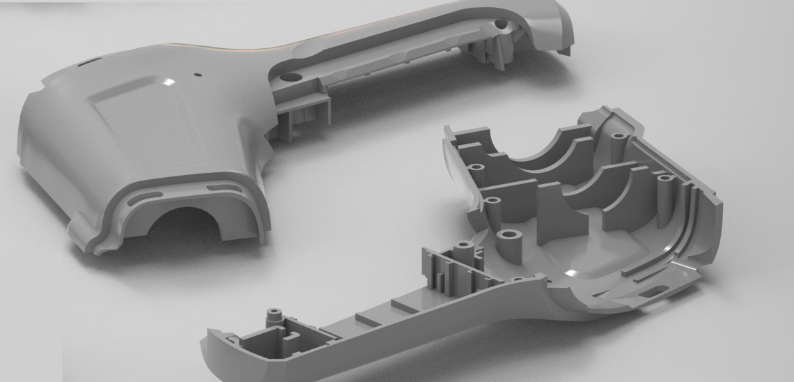

Protosys Technologies provides high-precision Injection Moulding, a manufacturing process used to produce complex plastic components with consistent accuracy. In this method, molten plastic is injected into a mould cavity, where it cools and solidifies into the final shape. Known for its speed, repeatability, and cost-efficiency, injection moulding is ideal for large-volume production across.

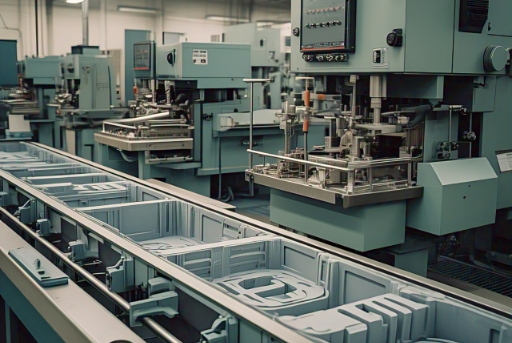

Protosys Technologies delivers custom injection molding, from on-demand prototypes to production moulding. With 90 to 830 ton machines in our Mumbai based facilities, we manufacture high-quality moulded parts of any size or complexity. We work with thermoplastics and thermosets, offering ISO 9001-C or tighter tolerances. Get expert guidance on quotes and solutions for seamless design-to-production process.

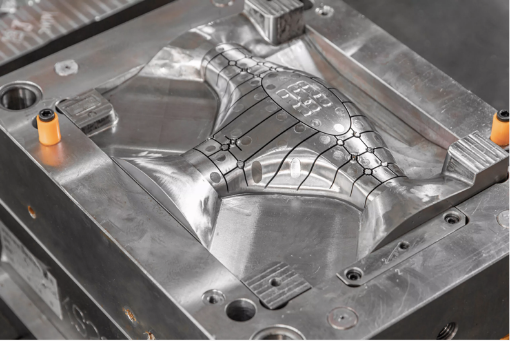

Get high-quality aluminum and steel injection molds customized to your needs. We achieve tight tolerances of 0.0008 in (0.02 mm) and offer free mold flow analysis. Ideal for mass production.

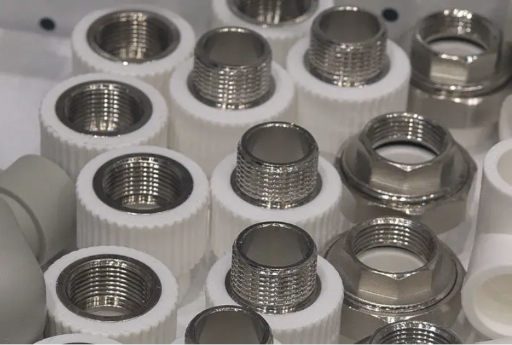

A subset of injection molding techniques where combines engineering plastics with pre-placed inserts in the mold cavity. It eliminates the need for fasteners.

Overmolding is a multi-step injection molding process that bonds plastic to another component (substrate), creating an integrated, durable product. Offers color and texture options.

Choose Protosys Technologies prototype molding services for fast, high-quality prototypes. With quick lead times, flexible materials, and expert DFM assistance, we help you validate designs efficiently and test functionability early.

Protosys Technologies low-volume production with aluminum tooling provides fast, cost-effective manufacturing of complex plastic parts in runs from hundreds to thousands. Ideal for design validation, inventory control, and a supply chain ready to flex with demand.

Protosys Technologies high-volume injection molding offers a fast, cost-effective way to mass-produce precise, identical parts. With advanced equipment and strict quality control, we ensure tight tolerances and consistent quality across a variety of plastic materials for your specific needs.

At Protosys Technology, advanced machines ranging from 20 to 130 tons are used to produce intricate parts with low tolerances. These machines are equipped with accessories that ensure optimal moulding conditions. A variety of engineered and high-performance plastics like Polyamide, Polycarbonate, PEEK, and PEI are used, sourced globally to meet client specifications. The facility supports insert and over moulding, while dedicated assembly and testing areas provide a one-stop solution for part production, assembly, and testing.

Shot Capacity : 20 g

Platen Distance (H x V) : 342 x 250 mm

Tie Bar Distance : 221 x 221 mm

Minimum Mould Height : 200 mm

Maximum Mould Height : 300 mm

Dimensional Accuracy :

Production Parts – 0.03-0.05 mm,

Proto Parts – 0.05-0.1 mm (can be achieved as per requirement)

Shot Capacity : 103 g

Platen Distance (H x V) : 520 x 520 mm

Tie Bar Distance : 355 x 355 mm

Minimum Mould Height : 210 mm

Maximum Mould Height : 400 mm

Dimensional Accuracy :

Production Parts – 0.03-0.05 mm,

Proto Parts – 0.05-0.1 mm (can be achieved as per requirement)

Shot Capacity : 130 g

Platen Distance (H x V) : 715 x 715 mm

Tie Bar Distance : 470 x 470 mm

Minimum Mould Height : 250 mm

Maximum Mould Height : 650 mm

Dimensional Accuracy :

Production Parts – 0.03-0.05 mm,

Proto Parts – 0.05-0.1 mm (can be achieved as per requirement)

Shot Capacity : 25 g

Platen Distance (H x V) : 400 x 400 mm

Tie Bar Distance : 270 x 270 mm

Minimum Mould Height : 225 mm

Maximum Mould Height : 325 mm

Dimensional Accuracy : Production Parts – 0.03-0.05 mm, Proto Parts – 0.05-0.1 mm (can be achieved as per requirement)

Shot Capacity :

Platen Distance (H x V) :

Tie Bar Distance :

Minimum Mould Height :

Maximum Mould Height :

Dimensional Accuracy : Production Parts – 0.03-0.05 mm, Proto Parts – 0.05-0.1 mm (can be achieved as per requirement)

Known for its toughness and easy machinability, ABS is commonly used in consumer products like toys, electronics, and automotive interior components due to its balance of strength and rigidity.

Known for its toughness and resistance to wear and abrasion, Polyamide is widely used in automotive and industrial applications. It offers excellent chemical resistance and high mechanical strength, making it ideal for parts that require durability.

This strong, transparent material is used for products requiring high impact resistance and clarity, such as eyewear lenses, automotive components, and electronic housings.

One of the most versatile plastics, Polypropylene is lightweight and offers excellent chemical resistance, making it a popular choice for packaging, automotive parts, and medical devices.

This high-performance plastic is known for its excellent chemical and heat resistance, making it suitable for aerospace, medical, and industrial applications that require durability at elevated temperatures.

A high-strength, thermally stable plastic, PEI is ideal for parts that need to perform in high-temperature environments. It is widely used in medical, aerospace, and electrical applications due to its excellent flame resistance and mechanical properties.

Known for its toughness and easy machinability, ABS is commonly used in consumer products like toys, electronics, and automotive interior components due to its balance of strength and rigidity.

Known for its toughness and resistance to wear and abrasion, Polyamide is widely used in automotive and industrial applications. It offers excellent chemical resistance and high mechanical strength, making it ideal for parts that require durability.

This strong, transparent material is used for products requiring high impact resistance and clarity, such as eyewear lenses, automotive components, and electronic housings.

One of the most versatile plastics, Polypropylene is lightweight and offers excellent chemical resistance, making it a popular choice for packaging, automotive parts, and medical devices.

This high-performance plastic is known for its excellent chemical and heat resistance, making it suitable for aerospace, medical, and industrial applications that require durability at elevated temperatures.