The automobile industry is undergoing a significant shift toward sustainability, focusing on eco-friendly materials and energy-efficient manufacturing. Protosys has been at the forefront of this movement, providing cutting-edge plastic solutions that help reduce carbon footprints while maintaining durability and performance. From lightweight components to recycled materials, Protosys is transforming how automobiles are designed and built.

One of the biggest challenges in the automotive sector is reducing vehicle weight without compromising strength. Protosys has developed high-performance, lightweight plastic components that replace traditional metal parts, leading to:

To support a greener future, Protosys integrates recycled plastics

and bio-based polymers into automobile manufacturing.

These materials help:

Modern vehicles demand materials that are both sustainable and resilient. Protosys provides advanced composites and nano-enhanced plastics that offer:

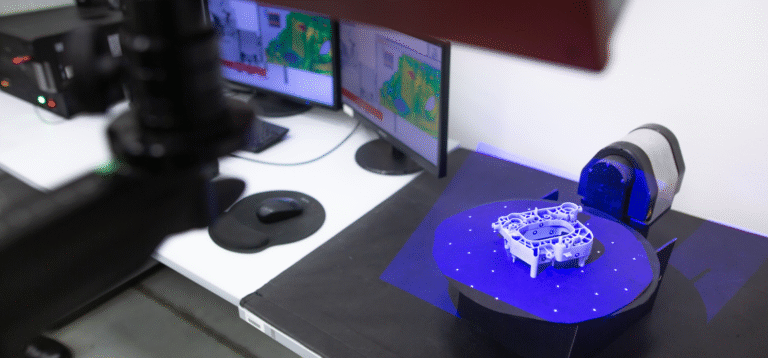

Protosys leverages 3D printing and advanced moulding techniques to:

With global automakers focusing on sustainability, Protosys continues to drive innovation by developing next-generation plastics that balance performance, cost-effectiveness, and environmental responsibility. By adopting circular economy practices, using renewable materials, and advancing plastic recycling, Protosys is shaping the future of sustainable mobility.

As the automotive industry accelerates toward greener alternatives, Protosys remains a trusted partner in creating smarter, lighter, and more sustainable vehicles for the world.

For any product development

inquiries contact us

How can we help you? Feel free to get in touch!